Every year, the Occupational Safety and Health Administration (OSHA) compiles its most frequently cited violations. Thus, we have a lot to learn about the different safety and fall prevention steps companies are, or are not, taking to protect their workers. Furthermore, at Nation Wide Ladder, we take safety seriously and want our customers to as well. Therefore, you can count on us to help you understand how to use and handle all of our products properly. Here are the top 8 OSHA safety violations explained.

-

Fall Protection

The general requirements for fall protection are simple. Employers must have fall safety protection systems that have the strength and integrity to support their employees. Likewise, employees must only work on surfaces that have the strength to withstand their weight.

-

Hazard Communication

If an employee works with chemicals or other hazardous materials, safety information must be available. For example, there should be a comprehensive program for container labeling, warning systems, safety data sheets, and employee training.

-

Respiratory Protection

Many occupations can come with the risk of respiratory contamination. Employers must take care to ensure that respirators are provided to limit exposure to harmful dust, fogs, fumes, mists, gases, smokes, sprays, or vapors. Also, they are responsible for the maintenance and care of the respiratory equipment as well.

-

Scaffolding

Without scaffolding, many jobs wouldn’t get done. But, many employers fail to meet safety standards. Scaffolding must withstand at least four-time the maximum load applied to guarantee it will not fail. There are a plethora of weight and safety requirements so users can stay safe.

-

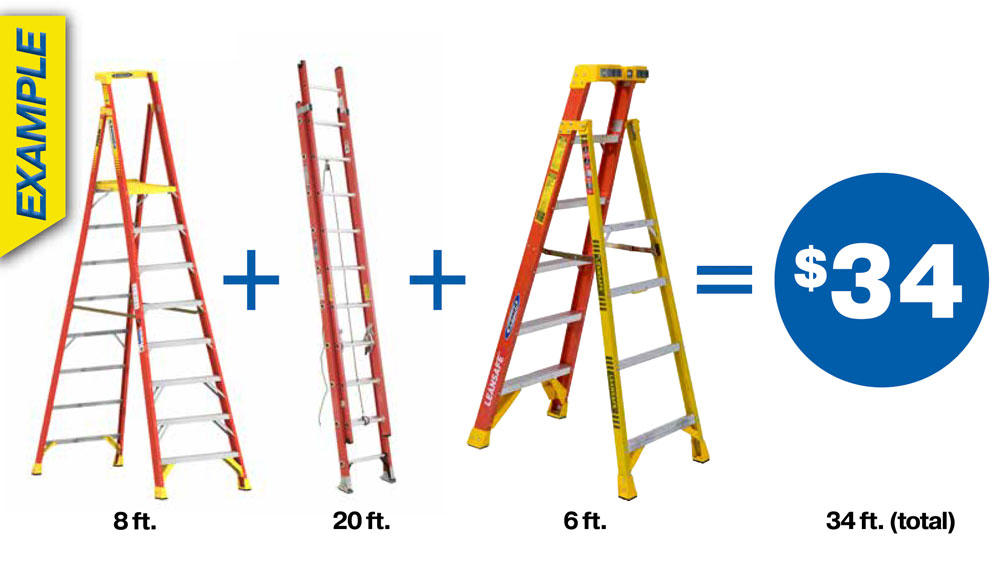

Ladders

Different types of ladders mean different ways of use. There are distinct ways that ladders must be placed to be operated correctly. Also, employers must make sure that the maximum load limit is not exceeded.

-

Lockout/Tagout

When machines are not working correctly, they need to be properly locked and tagged out. This standard applies to maintenance across the board, with a few exceptions if the machine can be properly shut down and unplugged solely by the mechanic.

-

Powered Industrial Trucks

Powered industrial truck safety applies to a variety of vehicle types. Employers must take care to meet standards on fire protection, design, maintenance, and use for fork trucks, tractors, platform lift trucks, motorized hand trucks, and other types of vehicles.

-

Fall Protection – Training Requirements

Properly training employees to meet fall protection requirements is imperative. Each employee must know how to put up, maintain, disassemble, and inspect any fall protection that is being used.

Nation Wide Ladders: Awareness on Safety and Fall Prevention

We offer a variety of tools and equipment to help companies with safety and fall prevention practices. To learn more, visit our website or give Nation Wide Ladders a call at 603-434-6911.